Lee Munsey, owner of Boundary Fencing, is a hands-on builder who loves problem-solving and continually improves the way work gets done.

When you’re looking for a long-term fencing solution from a reliable contractor, you’re trying to avoid two things: a low-quality fence that falls over, materials that don’t stand the test of time, and a job site experience that feels messy or uncertain. We caught up with Boundary Fencing owner Lee Munsey and received an in-depth primer on exactly how his reputable company handles Ok

anagan fence installation.

Lee’s method lasts longer because the fundamentals are correctly done, in a consistent sequence, with quality checks that happen before, during, and after installation. Check, check, check.

About Boundary Fencing

Since 2003, Boundary Fencing has been helping Okanagan homeowners, contractors, and project managers secure their properties with confidence. Lee Munsey, Owner of Boundary Fencing, aims to bring quality and accountability to an industry that often lacks both.

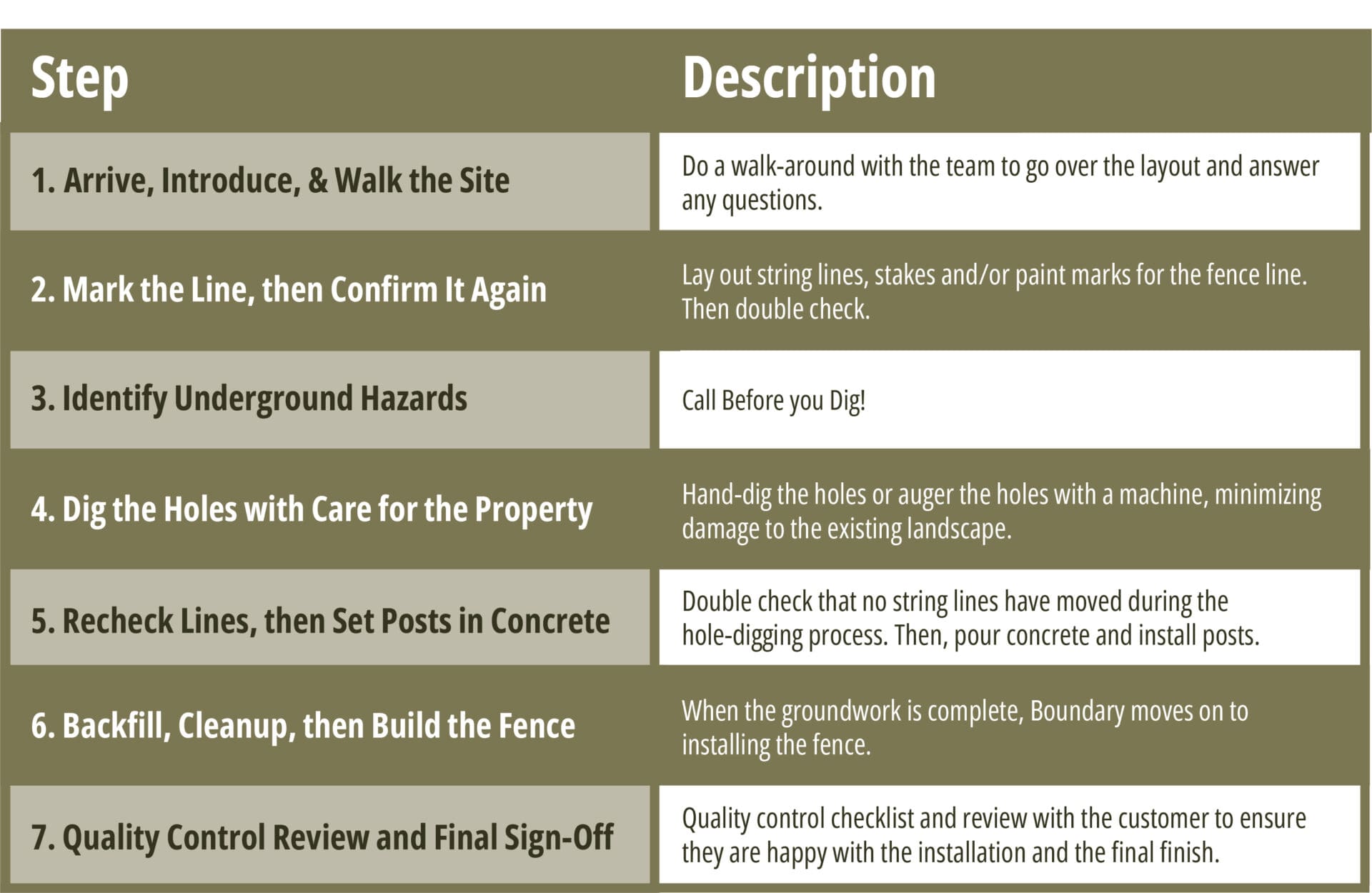

TL;DR: The Step-by-Step Boundary Fence Building Process

Quick review of Boundary Fencing’s step-by-step professional fence-building process.

Step 1: Arrive, Introduce, & Walk the Site

“Once our installers arrive on site, our first step is to have our lead installer introduce themselves to the customer,” Lee says. “We will have them do a walk-around with our team to go over the layout and answer any questions they (or the customer) may have.”

The customer sees the plan, questions get answered early, and nothing moves forward until the layout is understood.

Step 2: Mark the Line, then Confirm It Again

“Once that is done, we will lay out string lines, stakes and/or paint marks for the fence line,” Lee explains. “With those in place, we will again confirm with the customer that the layout is correct, and we can begin the installation process.”

That second confirmation matters. It protects the schedule, the relationship, and the final look.

Step 3: Identify Underground Hazards

“After we have the layout established, we will identify any underground hazards (gas & electrical lines) that we can,” Lee says. “We also take into consideration unlocatable or unmarked underground utilities, including irrigation and water lines.”

For builders and project managers, this is the difference between a smooth install and a surprise that derails other trades. We’ve all heard the phrase “Call Before You Dig,” and that’s not a step Boundary Fencing would ever dream of skipping.

Step 4: Dig the Holes with Care for the Property

“The next step is digging the holes,” Lee says. “We either hand-dig the holes or auger the holes with a machine. We do our best to mitigate damage to existing landscaping.”

For chain link fence installation, Lee is very clear about Boundary Fencing’s footing standards.

“For a 4-foot-high chain link fence, our standard footing dimensions are as follows: depth is 24 inches for line posts and 30 inches for terminal posts. The diameter is generally 8 to 10 inches for each post, depending on soil conditions.”

“Gate post footing dimensions are dependent on the gate size,” he adds. “Soil conditions sometimes dictate the need for deeper and or wider footings. These footing dimensions are sufficient for our frost conditions in the Okanagan Valley.”

If the fence is taller or built for higher loads, the spec changes.

“If we are installing a taller fence, privacy fence or commercial fence, we will increase the footing dimensions to compensate for wind load or to meet specifications required for the job.”

That is the foundation layer of durable commercial fencing. The loads get accounted for before the posts ever get set.

Step 5: Recheck Lines, then Set Posts in Concrete

“Once our post hole footings are dug, we double check that our string lines have not moved during the post hole digging process,” Lee says.

Then the crew stages the posts and begins setting.

“We will lay out all our posts and begin putting concrete in the post holes. The type of concrete we use, whether it be premixed cement, gravel and Portland or truck-poured concrete, depends on the job size and specifications or requirements for the job.”

Setting is done while the concrete is wet, with alignment controlled at the line.

“While the concrete is still wet, we will install our posts into the cement, ensuring all posts in line with the stringline are plumb with a level.”

And Boundary Fencing does not stop at a single check.

“Once the posts for a stretch of fence are complete or on longer lines (over 100 feet,) we will look back and visually inspect the line of posts. If any look off, we will re-level them.”

“The concrete will generally set up fast enough that we don’t have to brace the posts,” Lee adds.

Step 6: Backfill, Cleanup, then Build the Fence

“After the posts are set, we will cover the concrete footings with loose soil and either clean up and remove the remaining spoils from the site or place them in a customer-designated area.”

When the groundwork is done, the Okanagan fence installers get to the good part.

“With the groundwork complete, we move on to installing the fence,” Lee says. “The installation process varies depending on the material, chain link, vinyl, composite, or otherwise, but in all cases, we consider sight lines, terrain, and the final appearance of the fence once completed.”

That is the exciting part, where homeowners and neighbours start to see real progress with their own eyes.

Step 7: Quality Control Review and Final Sign-Off

Boundary Fencing finishes the way it starts: clear, documented, and customer-focused.

“After the fence installation is done, we complete our quality control checklist and review it with the customer to ensure they are happy with the installation and the final finish,” Lee says. “We always do our best to leave the job site as clean as possible.”

For homeowners, builders and project managers, that matters. The end of the job is not a scramble or a guessing game. It is a clean close-out, with a review, a sign-off, and a site you would be comfortable handing over to the next trade.

The Boundary Fencing team using specialized equipment to drill through bedrock for an infrastructure project in the Okanagan.

What About Bracing, Corners, Slopes, & Drift?

“It is not very often that we need to add bracing to the fence structure unless this is for a large commercial project. In that case, the bracing is generally noted in the job specification.”

And on keeping long lines straight:

“Drift isn’t usually an issue as larger projects are surveyed, and we can utilize the stakes to align our fence. If we are doing a long line without survey stakes, we have a specialty tool called a transit to establish a straight line.”

So the “secret” is not a gimmick. It is using the proper reference points and the right tools.

“Finishing Details” That Extend Lifespan

Lee refuses to sell a fantasy.

“There are not really any finishing details that are going to add to the longevity of the fence,” he says. “It just comes down to ensuring the use of high-quality products, not the cheapest products.”

Even with high-quality fencing materials, flaws can still occur. That is why quality control exists.

“Even though we do try to use the best quality material, there are sometimes flaws. That is why we have a quality control checklist… So all the material is checked before and after installation.”

He also points to one long-term decision that Boundary Fencing sticks to:

“One policy we do have is that we do not install wood posts for anything other than agricultural fence,” Lee says. “Even the treated wood products tend to rot, and we want to install a product that will last as long as possible.”

And for Okanagan conditions specifically:

“The main consideration for our climate is the wood material. Not installing wood posts in the ground (except for agricultural fences). The wood posts rot off relatively quickly. Treated wood, both pickets and square posts, tend to dry out in our climate and twist, check or bend due to the hot climate.”

Finally, Lee puts real weight behind the work.

“Boundary stands behind our installation for residential customers with a limited lifetime warranty on our workmanship,” he says.

The Professional Systems Behind the Install

“Our continuous and vigilant training, procedures, policies and education of our staff ensure constant improvement and consistency for our installations. Our installers are supplied with the best tools to complete the job to a high standard in the most efficient manner possible.”

Also, proper documentation.

“Our crews are supplied with a detailed work order, BC One Call documents, job specifications, site pictures and safety documents for each specific job.”

Boundary focuses on daily control and clarity so that they don’t end up with last-minute scrambling at the end of the job.

“During the installation, quality control documents are updated, and specifications are reviewed daily, followed by an after-installation review and sign off. We always do our best to maintain the same lead installer on a project so that communication is consistent and clear.”

Planning a Fence and Gate Installation in the Okanagan?

If you are weighing chain link fence, vinyl fencing, composite fencing, or a larger scope that includes gates, Boundary Fencing’s Vernon showroom is designed for side-by-side comparisons and practical answers, including high-quality fencing material options such as chain link fence supplies, composite fencing, and gate hardware.

Boundary Fencing keeps the process straightforward and documented from layout to final sign-off. Contact Lee and his team at Boundary Fencing today to begin planning your project.